Introduction

Data spaces are federated digital infrastructures that enable secure, sovereign, and interoperable data sharing among participants, based on commonly agreed standards, governance models, and trust frameworks. The key components of a data space include identity and access management, semantic interoperability (based on ontologies and data models), standardized APIs or connectors for system integration, and governance rules ensuring data sovereignty, including consent and usage control mechanisms. GAIA-X, Catena-X (automotive), AgriDataSpace (agriculture), and the Circular Economy Data Space are some examples of European Data spaces initiatives. These ecosystems promote the sharing of industrial, environmental, and operational data to drive innovation, improve productivity resilience, and regulatory compliance.

In this context, the textile industry is undergoing a digital transformation driven by sustainability, traceability, and compliance requirements. With increasingly consumer demand for transparency and ethical assessment, new EU regulations such as the Digital Product Passport (DPP), Corporate Sustainability Reporting Directive (CSRD), and Product Environmental Footprint (PEF), data is becoming a strategic asset. The concept of data as a product meaning data must be treated with the same care as a finished good, ensuring quality, documentation, accessibility, and governance becomes critical in this transition. Data spaces offer the technological and organizational foundation for enabling trustworthy data exchanges across the textile value chain. However, retrieving consistent, reliable, and complete data across a fragmented supply chain remains a key challenge to achieving true transparency and circularity claims.

Scope and Objectives of Data Spaces in Textile industry

Data spaces implementation in the textile industry can be a critical enabler for digital transition. Data space helps to achieve several objectives:

- It fosters interoperability between diverse systems such as ERP, PLM, and MES, enabling seamless and secure data exchange between actors throughout the supply chain.

- It ensures robust traceability from raw material sourcing to the final product and post-consumer phases.

- Data spaces are foundational to circular economy practices, supporting actions like reuse, recycling, and product lifecycle management.

- They enable alignment with evolving regulatory frameworks including the Digital Product Passport (DPP), and transparency by providing structured, verifiable, and auditable data flows.

This transparency not only strengthens consumer trust but also supports efforts like reshoring production within the EU under sustainable standards. However, challenges remain: implementing such systems involves significant costs for data collection and management, and risks persist regarding data reliability particularly for imported goods without strict controls. As DPP compliance becomes mandatory by 2026, large clothing producers will be legally required to issue passports, indirectly pushing their suppliers including SMEs to provide reliable, standardized data to remain in business. In this context, data spaces are a strategic asset for stakeholders across the textile and clothing sector, adopting a data space architecture not only ensures regulatory readiness but also strengthens transparency, operational efficiency, competitiveness and collaboration across complex supply networks.

From a technical point, data spaces rely on standardized protocols, secure connectors, identity management, and governance models to safeguard data sovereignty and safety.

The sm4rtenance Project: Enabling Data Space Pilots

The Sm4rtenance project (https://sm4rtenance.eu), co-funded under the Digital Europe Programme (DIGITAL) (G.A. 101123490), focuses on predictive maintenance and interoperable data sharing through cross-sectoral data spaces. Started on the 01 October 2023, this ongoing 36-month initiative serves as a testing ground for advanced data architectures in industrial settings.

By exploring both the technical and organizational dimensions of data sharing, sm4rtenance helps industry stakeholders transition from isolated data silos to collaborative digital ecosystems. It provides:

- A technical foundation for secure and scalable data sharing.

- Connector technologies to link industrial systems with data space infrastructure.

- Support for semantic modelling and ontology alignment.

- Best practices and guidelines for deploying data space pilots in real-world use cases, including the textile sector.

- A federated data portal to facilitate access, exchange, and governance of shared datasets across organizations.

- A focus on data space federation, supporting cross-sector integration and ensuring that textile use cases can interoperate with other domains such as manufacturing and energy.

Spotlight on the Piacenza Pilot Use Case

Within the Sm4rtenance project, the Piacenza Group is leading a pilot titled “Optimization of Production Performance through DPP,” designed to demonstrate how data spaces can foster circularity, transparency, and compliance with the Digital Product Passport (DPP) in the textile manufacturing sector. However, the implementation faces significant challenges. The inherent fragmentation of the textile value chain, combined with a lack of data standardization and limited trust among stakeholders, complicates data collection and transparency claims. Moreover, the effort and cost required to collect accurate and verifiable data, particularly from legacy systems and small suppliers, represent a considerable burden. All this increases the need for scalable, interoperable solutions.

The pilot's scope is to implement a data Space to ensure seamless data sharing between 2 main entities involved in the production steps inside of the Piacenza Group. As the processes from raw material to final product are sometimes carried out by Piacenza Cashmere and his partner, there is a clear need for the secure exchange of related information.

The pilot focuses on:

- Sharing key data points such as traceability, energy usage, and circularity indicators.

- Providing a data model suitable for interoperable data exchange.

- Enabling seamless management of both product and asset circularity, thereby demonstrating the added value of data spaces in sustainable manufacturing.

- Ensuring alignment with market expectations, particularly from the luxury fashion sector, which increasingly demands end-to-end product transparency.

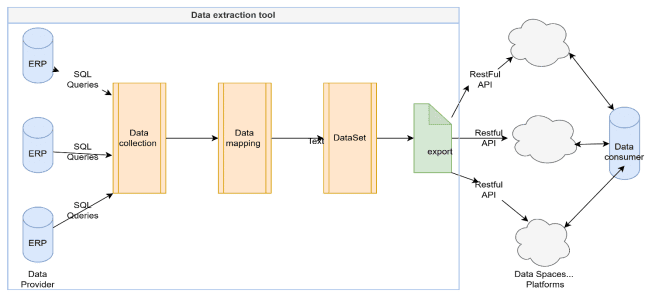

The implementation integrates ERP data extraction tools, standardized data models, and RESTful APIs to populate a federated, implementation and deployment of connectors to integrate both ERPs to the sm4rtenance ecosystem. This architecture ensures that both in-house and supplier data can be securely and efficiently shared, supporting real-time traceability.

The Piacenza’s ERP data extraction involves Domina’s data extraction tool, capable of interfacing with multiple textile ERP systems. The tool automates data collection while allowing the creation of flexible data models compatible with various platform standards and regulatory frameworks. It is capable of retrieving specific data from ERP through different certification compliance, making it a scalable and reusable solution for broader industry adoption.

The Piacenza and Piacenza's Partner MVDS Implementation: Inter-Company Data Exchange

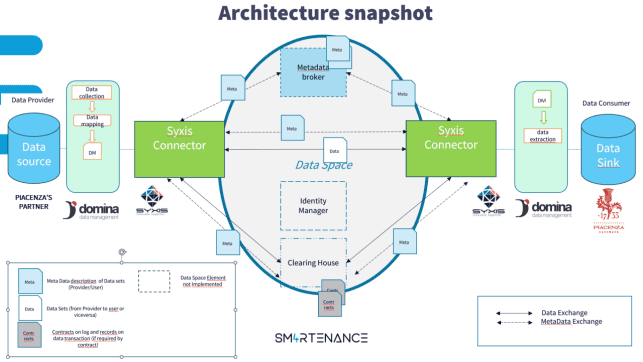

The Piacenza and his Partner collaboration implements a Minimum Viable Data Space architecture connecting two established textile manufacturers through secure connector infrastructure. This implementation demonstrates how two distinct entities within the textile value chain can establish secure, standardized data exchange mechanisms while maintaining data sovereignty and regulatory compliance.

Technical Architecture and Component Selection

The Piacenza and his Partner MVDS leverages proven open source technologies to minimize implementation complexity while ensuring scalability and interoperability. The core architecture consists of:

Sovity Community Edition (CE) 10.4.2 Connectors: Both Piacenza and his Partner deploy Sovity CE connectors, utilizing the open source variant to avoid vendor lock in and ensure transparency in data governance mechanisms. The CE 10.4.2 version provides robust support for the Dataspace Protocol (DSP), ODRL-based policy enforcement, and seamless integration with existing ERP systems through standardized APIs.

Sovity DAPS Based on Keycloak: The MVDS implements a Sovity Dynamic Attribute Provisioning Service (DAPS) built on Keycloak infrastructure, which manages participant identities and issues Dynamic Attribute Tokens (DATs) for secure connector authentication. This configuration enables trusted communication between the two connectors while maintaining the flexibility to scale to additional participants in the future.

Sovity Portal: The data space incorporates a Sovity Portal that provides a user-friendly interface for data space management, allowing both organizations to monitor data exchanges, manage usage policies, and oversee connector operations through a centralized dashboard.

Policy Framework and Data Sovereignty

The MVDS implementation incorporates granular usage policies expressed in ODRL format, ensuring that each data exchange respects the data owner's sovereignty requirements. Key policy restrictions include purpose limitation for traceability and sustainability reporting, retention policies aligned with production cycles.

Integration with Existing Systems

Both organizations leverage the same Domina data extraction tools utilized in the broader Sm4rtenance project, ensuring consistency in data quality and format standardization. The connectors interface with existing ERP systems through RESTful APIs, enabling real-time data synchronization without disrupting established business processes.

The modular architecture allows for incremental expansion, positioning the MVDS as a foundation for future integration with additional suppliers, logistics partners, and certification bodies within the extended textile ecosystem.

Operational Benefits and Strategic Value

The MVDS architecture's inherent scalability ensures that additional textile industry participants can join the ecosystem with minimal technical overhead, positioning this implementation as a model for broader industry adoption of data space technologies. This implementation exemplifies how the textile industry can leverage data spaces as strategic enablers of collaborative innovation and operational excellence across traditionally fragmented supply networks.

Benefits for the Textile Ecosystem

The solution developed by Syxis and Domina within the Piacenza use case can be adopted by other textile companies due to its significant advantages and scalability:

- Data extraction compliant with various certifications and platforms from ERP systems

- Improved transparency and traceability across the supply chain.

- Streamlined compliance with regulatory frameworks like DPP.

- Greater interoperability among production, certification, and logistics systems.

- Increased trust and collaboration among brands, suppliers, and recyclers by ensuring sovereignty and safety of data

- Data-driven decision making and enhanced lifecycle management for productivity improvement.

- Interoperability with other data space ecosystems ensuring through the integration of Sovity connectors.

Challenges

Despite the potential, significant challenges must be addressed to enable effective textile data space deployment:

- Standardizing data formats and ontologies remains difficult due to the diversity of data types and lack of widely adopted sector-specific standards.

- Integrating legacy systems poses a barrier, as many SMEs in the textile industry still operate with outdated or proprietary software that cannot easily communicate with external platforms.

- Defining governance frameworks is complex, requiring multi-stakeholder alignment on data ownership, access rights, liability, and trust-building measures.

- Workforce readiness is often underestimated; employees must be trained not only on technical tools but also on data culture, compliance obligations, and collaborative data practices.

Overcoming these challenges will require sector-wide coordination, targeted investment in digital skills.

Conclusion

The Piacenza pilot within the Sm4rtenance project demonstrates how data spaces can be integrated and its benefits for the textile sector by enabling secure, standardized, and interoperable data exchange across its particularly fragmented value chains. The solution co-developed by Domina and Syxis combines ERP data extraction tools, semantic data modelling, and connector-based data sharing to implement and deploy a textile data space. Given its modular architecture and compatibility with multiple textile ERP systems, this approach is highly transferable. Textile companies already engaged in digital transformation, are ideally positioned to adopt this solution. By leveraging the same data space infrastructure, they can achieve regulatory readiness, enhance transparency, and unlock new value from their data ecosystems.