The LPS-5G system

The LPS-5G system (Local-Positioning-System embedded in the 5G ecosystem) is a next-generation industrial safety and tracking solution developed within a European innovation project Target-X. Designed for dynamic industrial environments, it enhances real-time worker protection and asset localization by leveraging the high bandwidth and ultra-reliable, low-latency communication (URLLC) capabilities of 5G networks. As digital transformation advances across manufacturing and logistics, LPS-5G addresses a key Industry 4.0 challenge by enabling intelligent, responsive systems that proactively reduce collision risks and support smarter operational oversight.

Scope and Objectives

The LPS-5G system is designed to accurately localize workers and mobile assets in real time and prevent collisions through proximity-based alerting mechanisms. These core objectives are fully aligned with Industry 4.0 priorities, supporting digital transformation across smart factories, logistics hubs, and automated production lines. By enabling responsive, location-aware safety systems, LPS-5G contributes to more intelligent, efficient, and secure industrial operations.

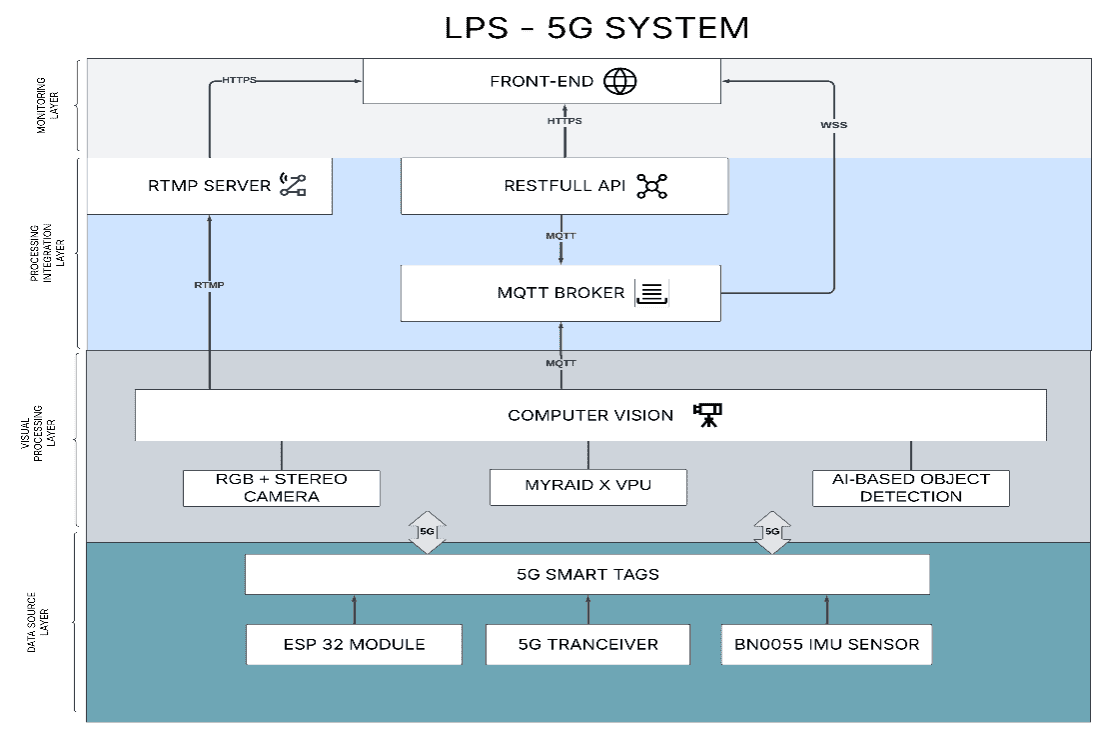

Implementation Overview

The LPS-5G system combines a robust hardware and software stack to deliver real-time localization and safety in industrial environments. Its architecture is designed for high responsiveness, modularity, and adaptability to support time-sensitive operations.

Hardware Components:

- Smart tags equipped with inertial sensors (IMUs) for precise motion tracking

- Industrial cameras using ArUco markers for visual asset recognition

- Edge computing devices to enable real-time, low-latency data processing at the source

- Private and public 5G infrastructure to ensure high-performance, reliable communication

Software Architecture:

- Computer vision modules for object detection and identification

- Kalman filter-based fusion engine that integrates IMU and visual data for enhanced accuracy

- MQTT-based communication protocols to ensure efficient, lightweight data exchange

- A real-time dashboard interface that enables live monitoring, triggers safety alerts, and provides traceable event logs.

Together, these integrated components form a flexible and scalable platform suited to diverse industrial settings supporting both small facilities and large, complex production environments.

Key Challenges

The development and deployment of the LPS-5G system offered valuable lessons that shaped its technical robustness and real-world applicability. Several challenges were addressed to ensure the system could perform reliably in complex industrial environments:

- Latency variability in public 5G networks required the implementation of adaptive safety thresholds to maintain consistent and reliable alerting.

- Accurate sensor fusion demanded precise temporal synchronization between inertial measurement units (IMUs) and computer vision inputs.

- Network setup and optimization involved configuring custom MQTT brokers and deploying edge nodes within private 5G infrastructures to guarantee low-latency, secure communication.

- Real-world validation in industrial settings—such as environments with robotic arms and moving forklifts—was essential to test and confirm the system’s responsiveness, alert precision, and positioning accuracy under dynamic operating conditions.

These insights guided key architectural and design decisions, helping to ensure the LPS-5G system is both technically sound and practically effective in demanding scenarios.

Field Results

In pilot deployments, the LPS-5G system demonstrated:

- Average data transmission latency below 100 ms in private 5G environments

- Consistent alert performance during dynamic interactions between humans and machines

- Scalability and reliability even in complex, noise-prone industrial settings

These results underline the viability of private 5G networks for time-sensitive industrial applications and highlight the platform’s readiness for production environments.

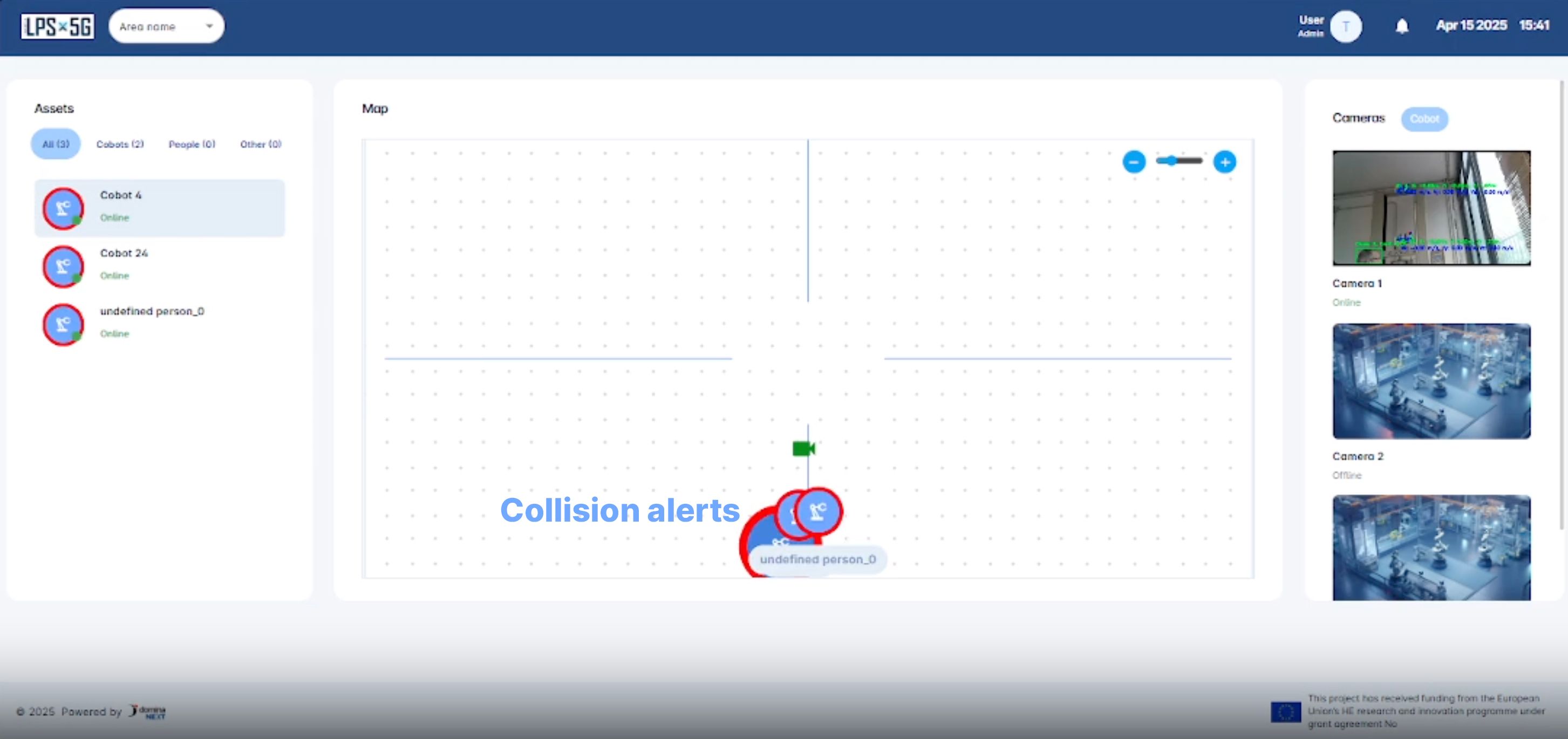

Monitoring Dashboard

The LPS-5G monitoring dashboard serves as the system’s central hub, delivering real-time visibility, actionable insights, and high-level control across industrial environments. Designed for scalability and ease of use, it supports both small facilities and large production plants.

Core Features:

- Live map visualization of workers and machines within defined safety zones

- Instant visual alerts triggered when proximity thresholds are breached

- Complete traceability of safety events for compliance, audit, and root-cause analysis

Key Benefits: - Improved worker safety through continuous monitoring and predictive alerting

- Minimized downtime by enabling proactive responses and smoother operations

- Data-driven decision-making with real-time analytics on risk areas, movement trends, and operational bottlenecks

With its intuitive interface and robust functionality, the dashboard empowers industrial stakeholders to manage safety, optimize workflows, and ensure compliance making it a vital component of the LPS-5G system and a valuable tool for any modern industrial operation.

Benefits for Industry

LPS-5G is more than a safety system—it’s a strategic enabler of digital transformation.

Key benefits include:

- Increased worker protection and fewer incidents

- Operational transparency through real-time tracking and alerting

- Regulatory compliance support with auditable safety data

- Future-proof architecture, ready to integrate with data spaces and advanced industrial IoT infrastructures

By delivering modular scalability, private network support, and smart monitoring capabilities, LPS-5G provides a clear competitive advantage to stakeholders ready to embrace the future of industrial safety.

By fusing sensor intelligence, real-time 5G communication, and intuitive monitoring tools, LPS-5G is more than a safety platform it’s a strategic enabler of smart manufacturing. Its modular design, compatibility with emerging data spaces, and support for private network infrastructure make it a future-proof solution tailored for modern industry.

LPS-5G delivers not just technology, but a competitive advantage through enhanced safety, performance transparency, and scalable digital integration.

The LPS-5G system was developed with support from the European-funded Target-X project, as part of its Second Open Call. Target-X aims to accelerate the adoption of 5G and 6G technologies in key industrial sectors by supporting innovative use cases and cross-industry trials. The initiative was carried out in collaboration with our partner Univerlab, who led the development and integration of the hardware components.